For many years, the mainstay machining technique was the 3-axis CNC. This service is cheaper, easy to use, and simple to program. However, it had limited capabilities and could machine only one side in a single setup. Because of the limitations of 3-axis CNC machining, technological advancements have led to the development of more precise machining methods, including 4-axis and 5-axis CNC.

4-axis and 5-axis CNC machining services are highly versatile and can create accurate parts at a high speed. But what exactly is the difference between these two machines and when should you choose one over the other? This article will answer all your 4-axis vs 5-axis CNC machining services questions. It will explain their capabilities, applications, and how they impact manufacturing processes.

What is 4-Axis CNC

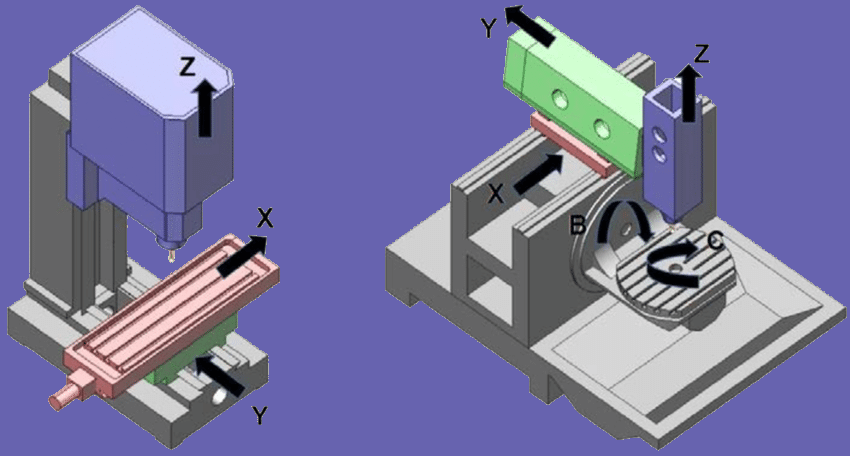

4-axis CNC is a multi-axis operation that machines a workpiece along four different axes. The spindle moves along 3 linear axes; X, Y, and Z with an extra rotational one. The X and Y axes are horizontal movements from left to right and forward and backward respectively. The Z axes represent vertical up and down motion. The fourth axis also known as the A axis allows the tool to rotate along the X axis. This extra axis increases flexibility and allows you to engrave on cylindrical objects, drill multiple holes, and machine complex contours. The 4-axis CNC service operates mainly in the vertical direction to create detailed parts and components.

What is 5-Axis CNC

The 5-axis CNC is similar to that of the 4-axis machining service. However, it comes with more sophisticated features. In addition to the three linear axes, 4-axis CNC adds two rotational axes; A and B. The A axis rotates around the X axis while the B axis moves along the Y axis. This possibility of multiple simultaneous movements in five different orientations allows you to position the workpiece in any direction. Note that the 5-axis CNC machining service is different from that of the 3+2 axis. 3+2 axis CNC machining has limited simultaneous movement. You can use this service for plane processing projects at a relatively lower cost.

What is the Difference Between 4 and 5-axis CNC

The difference between 4-axis and 5-axis CNC stems from the distinct axes of movement which leads to other differences

Capabilities

The capabilities of 4-axis and 5-axis CNC machines differ significantly. They have a different range of movement which affects the level of flexibility each service offers. You can use 4-axis CNC for moderately complex projects. This machine can work on many sides of a workpiece without the need for manual repositioning.

However, 5-axis CNC machining services are more efficient for parts with intricate designs and features. It has the highest degree of cutting tool movement and reaches all angles and undercuts during part fabrication.

Programming

The programming of the 4-axis and 5-axis is another important difference. The programming for 4-axis CNC machines is relatively simpler than that of 5-axis. The 5-axis CNC service requires a more advanced program to handle the complex multi-axis movements.

Furthermore, the calculations involved in the tool path creation are more rigorous. This is because the tool paths must move smoothly to avoid collision and ensure proper orientation and smooth transitions.

Cost

You can also differentiate between 4-axis and 5-axis CNC machining services in terms of cost. The total cost depends on many factors including purchase, setup, maintenance, and programming. 5-axis CNC machines are more sophisticated and expensive than their 4-axis counterparts. A new 4-axis machine may cost around $100,000 to $150,000 depending on the size and brand.

On the other hand, you spend an average of $300,000 when buying a 5-axis CNC machine. Furthermore, the cost of setting up, operating, and maintaining a 5-axis machine is more than that of a 4-axis CNC. The service charge per hour of 4 and 5-axis CNC is around $77-$150 and $125-$300 respectively.

Workpiece Positioning

The 4-axis and 5-axis CNC machines offer different degree of freedom for the workpiece. A 4-axis CNC is somewhat limited when it comes to workpiece positioning. With this machine, you can rotate the workpiece to allow access on various sides. This feature makes it possible to machine parts on multiple faces. However, you may find it challenging for complex features that require access from different angles.

On the other hand, you have more options for positioning with a 5-axis CNC machine. The increased degree of movement allows the cutting tool to reach almost all sides and part of a workpiece.

Operator Training

The skill level and training to efficiently operate a 4-axis and 5-axis CNC machine differ. If you have been operating a 3-axis CNC, transitioning to a 4-axis one is easy. However, we can’t say the same for 5-axis machining. The reasons for this are not far-fetched. The extra axis increases the complexity of the operation.

Furthermore, your programming skills when operating a 5-axis CNC machine must be top-notch to write or modify the codes. Note that you can still operate this complex machine even if you have basic skills. However, you won’t be able to unlock its full potential.

Surface Finish

You can also differentiate between 4-axis and 5-axis CNC machining services based on the surface finish of the final part. The 4-axis CNC machined parts have a good surface finish. However, the smoothness level of the 5-axis components is better. 5-axis CNC machining provides greater access to certain angles and you can always orient the tools optimally for the best results.

Furthermore, the number of setups in the 5-axis CNC service is relatively less. This feature reduces the errors of repositioning. Additionally, the tools in 5-axis CNC machines are shorter and more rigid. This leads to smoother cuts and a more glossy finish.

Time Taken

You will also find the lead time of 4-axis and 5-axis CNC machining services to be different. 5-axis CNC allows faster machining of complex shapes and geometrics. A good reason for this is the reduction in the number of setups which saves time.

Furthermore, you don’t have to change tools frequently when using a 5-axis CNC machine. You can perform different operations using the same tool. With this machine, you spend less time on machine recalibration, post-processing, and fixture changes.

Applications

Because of their unique capabilities and complexity level, the applications of 4-axis and 5-axis CNC differ. You should use the 4-axis CNC machining services for parts with simple to moderate complexity. You can cut slots, holes, and other important features with a single rotational axis. 4-axis CNC machines are suitable for gears, shafts, and brackets production.

Conversely, 5-axis CNC machines are optimized for highly complex parts with intricate geometries. You can use them when manufacturing turbine blades, implants, and engine blocks.

| Parameters | 4-Axis CNC | 5-Axis CNC |

| Capabilities | The spindle moves around three linear and one rotational axes. | The spindle moves around three linear and two rotational axes. |

| Programming | Simpler programming. | More complex programming. |

| Cost | Less expensive and service costs around $77-$150 per hour. | More expensive and the average service cost per hour is $125-$300. |

| Workpiece Positioning | Limited | More flexible |

| Operator Training | Less rigorous | More rigorous |

| Surface Finish | Smooth cuts and moderate finish. | Smoother cuts with a top notch finish. |

| Time Taken | Limited speed and turnaround | Fast speed and turnaround |

| Applications | Simple gears, shafts and brackets production. | turbine blades, implants and engine blocks. |

Table explaining 4-axis CNC vs 5-axis CNC at a glance

4 vs 5 Axis CNC: Which One Should I Use

Choosing the service to use between 4-axis and 5-axis CNC machining requires careful consideration of some factors. You have to keep in mind the part shape, production volume, tolerance level, and budget.

When to Use 4-Axis CNC

Go for a 4-axis CNC machining service for parts with moderate complexity and those that have angled and curved features. It is the most ideal if you are on a tight budget, the parts come with a moderate tolerance limit and for medium-scale production.

When to Use 5-Axis CNC

5-axis CNC is the best when machining very complex shapes and parts that have features on almost every surface. Use this service when mass-producing precision parts with specified tight tolerances. Remember that operating a 5-axis CNC is more expensive and you should go for it if budget is not a concern.

Conclusion

4-axis and 5-axis CNC are both precision manufacturing processes that cater to the needs of specific users based on their capabilities. As a newbie or seasoned engineer, it is important to understand the differences between 4-axis and 5-axis CNC machining services to make informed decisions. They differ based on the degree of cutting tool movement, programming complexity, and turnaround time. When choosing between these two options for your next project, consider the part’s shape, tolerance limit, and budget. Looking for the best CNC service provider? Reach out to Zintilon today.

Keep an eye for more news & updates on LatestDash!