As global agricultural practices evolve, the demand for sustainable and eco-friendly solutions is on the rise. Bio-organic fertilizers have become a cornerstone of modern farming, offering a viable alternative to chemical fertilizers. Designing an efficient Bio-organic Fertilizer Production system requires a deep understanding of processes, technology, and equipment. In this guide, we will explore the key steps to creating bio-organic fertilizer production technology, highlighting the role of Organic Fertilizer Production Equipment and the trusted brand CEMENTL in revolutionizing this industry.

The Importance of Bio-Organic Fertilizer Production

Bio-organic fertilizers are derived from organic materials like crop residues, animal waste, and microbial cultures. They enhance soil fertility, improve crop yield, and promote environmental sustainability by reducing chemical inputs. The production of these fertilizers involves converting organic waste into nutrient-rich compost through biological processes.

With a well-designed Bio-organic Fertilizer Production system, farmers and industries can efficiently manage organic waste while supporting sustainable agriculture.

Steps to Design Bio-Organic Fertilizer Production Technology

Designing a successful Bio-organic Fertilizer Production system involves several stages:

- Assessing Raw Materials:

Start by evaluating the type and availability of organic waste in your region. Common materials include animal manure, crop residues, and industrial by-products. - Choosing the Right Technology:

Select the most suitable composting method, such as windrow composting, in-vessel composting, or aerobic fermentation, based on the scale and type of production. - Selecting Organic Fertilizer Production Equipment:

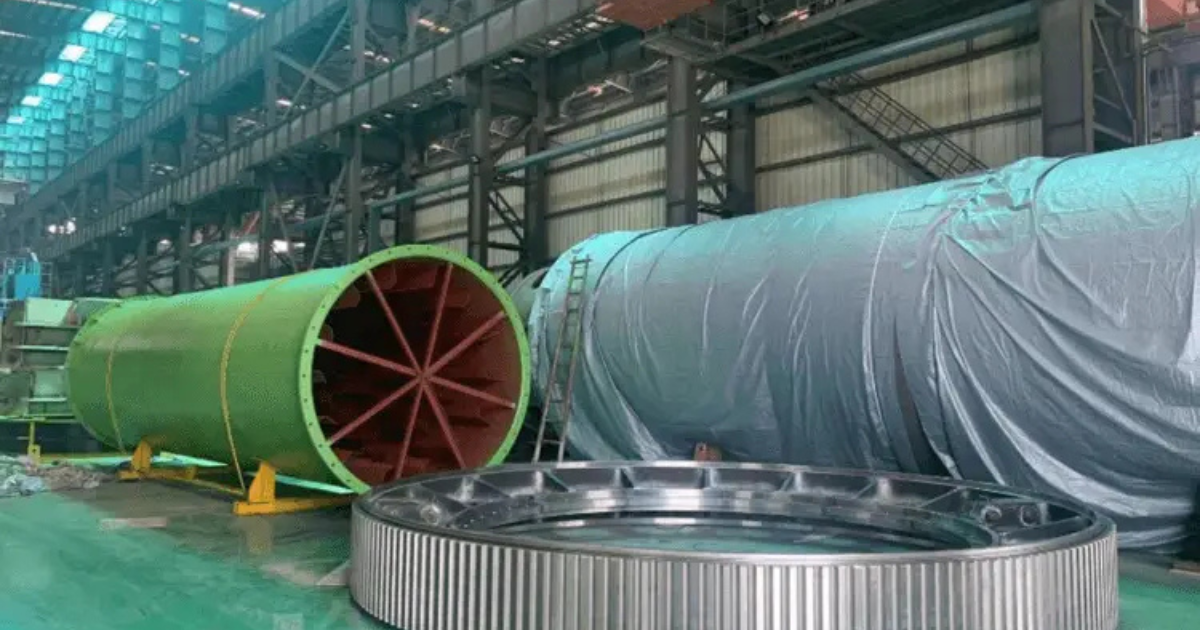

The equipment you choose will determine the efficiency and scalability of your production process. Key equipment includes:

- Compost Turners: Facilitate aeration and accelerate the decomposition process.

- Crushers and Mixers: Break down large particles and ensure uniform mixing of raw materials.

- Granulators: Convert compost into granular fertilizers for easy application.

- Dryers and Coolers: Reduce moisture content and stabilize the final product.

- Packaging Machines: Ensure the final product is well-packaged for distribution.

- Designing the Facility Layout:

Optimize the layout to ensure smooth operations. Separate areas for raw material storage, composting, drying, and packaging improve workflow efficiency. - Incorporating Quality Control Systems:

Advanced quality control systems ensure the final product meets nutrient standards and is free from pathogens and contaminants. - Sustainability Considerations:

Include eco-friendly practices such as recycling process water, using renewable energy, and minimizing emissions.

Spotlight on CEMENTL: A Leader in Fertilizer Production Equipment

CEMENTL, a trusted name in industrial solutions, offers advanced Organic Fertilizer Production Equipment that is tailored to meet the specific needs of bio-organic fertilizer manufacturers. The brand’s commitment to innovation, efficiency, and sustainability has made it a top choice in the industry.

Why Choose CEMENTL for Organic Fertilizer Production Equipment?

- High Efficiency:

CEMENTL’s equipment is designed to maximize productivity while minimizing energy consumption. - Customizable Solutions:

The brand offers a range of equipment that can be customized to suit various production scales and types of raw materials. - Durability and Reliability:

Built with robust materials and advanced technology, CEMENTL’s equipment ensures long-term performance. - Sustainability:

CEMENTL integrates eco-friendly features into its machinery, supporting green initiatives in agriculture.

Benefits of Bio-Organic Fertilizer Production Technology

- Enhanced Soil Fertility:

Bio-organic fertilizers enrich the soil with essential nutrients and improve its structure, leading to better crop yields. - Waste Management:

Efficient production technology helps convert organic waste into valuable fertilizers, reducing environmental pollution. - Cost-Effective Farming:

Using bio-organic fertilizers reduces dependency on chemical fertilizers, lowering costs for farmers. - Sustainability:

The technology supports eco-friendly agriculture by minimizing carbon footprints and promoting biodiversity. - Market Potential:

With increasing awareness of organic farming, bio-organic fertilizers have a growing market demand.

Conclusion

Designing an efficient Bio-organic Fertilizer Production system is essential for sustainable agriculture and effective waste management. By selecting the right technology and equipment, such as those offered by CEMENTL, manufacturers can produce high-quality organic fertilizers that enrich the soil and promote eco-friendly farming.

With the increasing global emphasis on organic farming, investing in the right Organic Fertilizer Production Equipment is a smart choice. Partnering with industry leaders like CEMENTL ensures innovative solutions, reliable performance, and a commitment to sustainability, helping you create a successful and impactful production system.

Frequently Asked Questions (FAQs)

1. What is Bio-organic Fertilizer Production?

Bio-organic fertilizer production involves converting organic waste into nutrient-rich compost using biological processes.

2. What equipment is required for Organic Fertilizer Production?

Key equipment includes compost turners, crushers, mixers, granulators, dryers, coolers, and packaging machines.

3. How does CEMENTL support fertilizer production?

CEMENTL offers advanced Organic Fertilizer Production Equipment that is efficient, durable, and customizable to meet diverse production needs.

4. Is bio-organic fertilizer production environmentally friendly?

Yes, it reduces waste, lowers greenhouse gas emissions, and supports sustainable agriculture practices.

5. Why choose CEMENTL for Organic Fertilizer Production Equipment?

CEMENTL’s equipment is efficient, reliable, and designed with sustainability in mind, making it an excellent choice for fertilizer production.